THE GOAL

Water temperature control for pressure testing during periodic maintenance of heat exchangers and hydraulic capacities.

Water temperature control for pressure testing during periodic maintenance of heat exchangers and hydraulic capacities.

Pressurized test water heating

As part of regulatory maintenance operations, it is necessary to ensure that hydraulic systems are in perfect condition before they are put back into service.

One of the steps in this process is to carry out hydraulic trials to test the strength and integrity of the equipment. Before carrying out these tests, the water used for the pressure test must be heated, to ensure that its temperature is in line with that which it will reach under normal operating conditions.

This temperature control enables more accurate test results to be obtained, representative of the actual performance of hydraulic systems once they have been put back into service.

By adjusting the test water temperature to that of normal use, we also ensure a more accurate simulation of the operating conditions to which equipment will be subjected once maintenance is complete, thus minimizing the potential risks of malfunction or failure.

Supply of Process water heating capacity to match customer requirements

The amount of heat required to heat the water is closely related to the volume of water to be heated, as well as to heat losses in the circuits under test. Calculating this heating capacity can be complex, due to a number of unpredictable factors.

In this context, having considerable heating power that can be adapted to real needs is a Tibbloc advantage.

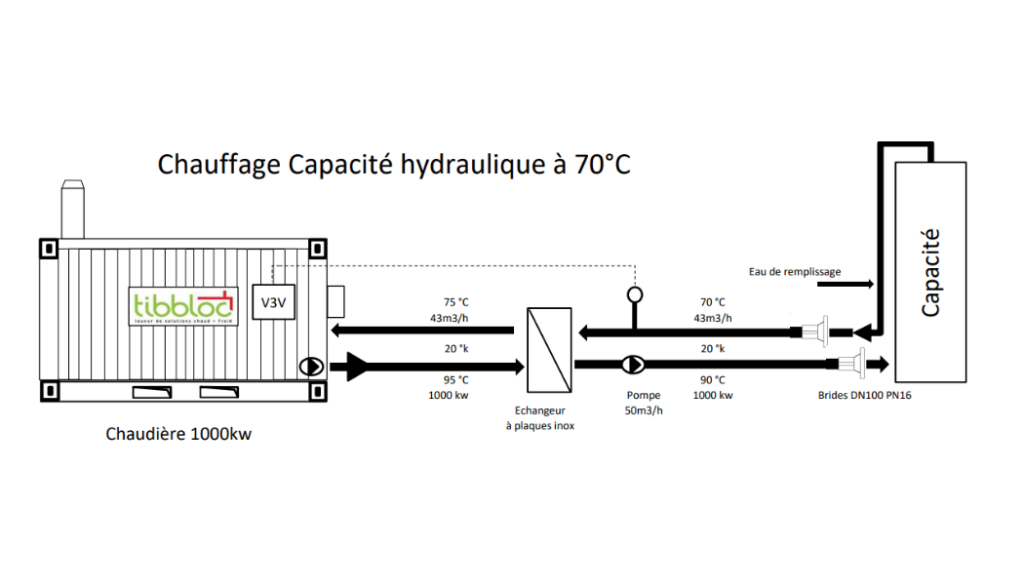

With a test pressure of 3 bar and a nominal temperature difference between water inlet and outlet of 70°C, as well as a pump flow rate of 43 m³/h, the heating capacity required may vary according to the size of the system and the specific conditions of each test.

Hot water production rental 1 MW

The installation of a boiler room includes several essential elements to ensure optimal operation. This includes :

Without fixed capital investment

Boiler house 1 MW

10 m³ fuel oil delivery

24/7 on-call

Partnerships with carriers